NEWS | SOFTWARE | SHEET

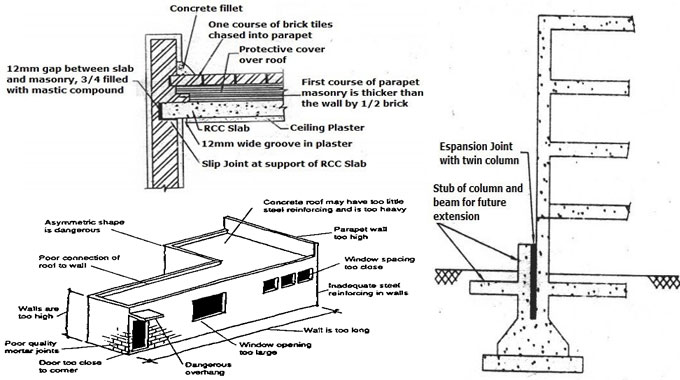

High-quality Construction Methods and Approaches to Avert Architectural Harm

High-quality construction methods and approaches must be pursued to avert happening of formational destructions that could take place for the duration of habitation and along duration of the building. A building has to experience various phases in composition procedure. Every single phase of formation is significant to ensure that the building now created will not meet deterioration controlled by any ordinary conditions.

Next are the high-quality formation methods and facilities that must be pursued for high-quality and robust formation of building:

1. Construction job: Construction job in a building must be executed in consistent attempts in the direction of the entire sections of the building to avert unequal damages of infrastructure as a result of mismatched burdening. This will avert the bursting of building walls and as well as additional constructional components. Dissimilarity in the elevation of roofing in various sections of a structure must generally not go beyond 1 meter at any moment for the duration of formation.

2. Cement job: In supported concrete parts for example support pillars and bricks which are accountable to bend noticeably under burden, elimination of amassing and requirement of burden must be delayed at most one calendar month in order that cement puts on enough soundness earlier than it endures the burden.

3. Reinforced Cement Concrete Structure: As long as feasible structure should be finished earlier than preliminary task of partition walls all for plaster coating and segmenting.

Task of formation of frame walls and embankment must be put off till a later time as far as feasible and must continue out of tip to downhill.

4. Cementing: Once cementing is to be completed on building, cement junctions in construction must be excavated to 10 millimeter distance down as long as the plaster is green. Cementing must be completed once construction has been correctly recovered and permitted to arid in an effort to experience early contraction earlier than cement.

5. Cement and stripes floor: Control junction must be added in the cement and stripes flooring even if through establishing floors in every other panels or through letting segment of glass, aluminum or any synthetic substance at bounded period in framework model. Once floor covering is to be established on reinforced cement concrete slab, even if a support technique of emerald cement must be offered in the midst of the Reinforced Cement Concrete brick and the floor covering or appearance of brick must be well toughened, purified and prepared through concrete residue earlier than setting of basement.

6. Reinforced Cement Concrete ceiling brick: The tip of the brick must be offered with sufficient padding or preventive concealment along with some excessive brightness surface protection to verify the thermal motion of the brick and resulting breaking in upholding wall and block/separation wall.

7. Condition of polished, strips or stripe floor on standing exterior: Prior to establishing of these floor coverings on upstanding exterior ambience part must be permitted to experience drift by cause of flexible deformity, contraction and crawl or else floor coverings are in all probability to break and dislocated.

8. Reinforced Cement Concrete job in uncovered situation: For Reinforced Cement Concrete task in uncovered situation specifically door covers, verandas, housetops, open patio, and so on, to avert contraction and compression breaks, tolerable amount of atmospheric conditions support must be offered. In suchlike condition amount must be incremented by fifty to hundred percent of the least quantity set.

9. Coating on wall: Finalizing substance specifically paint and coating, and all that must be executed once the paste has dehydrated and has experienced dehydrating contraction.

10. Speed of formation: The formation agenda and the speed of formation must be synchronized to make sure.

To read the complete article, go through the following link: theconstructor.org