NEWS | SOFTWARE | SHEET

Workability of Concrete by Slump Cone Test

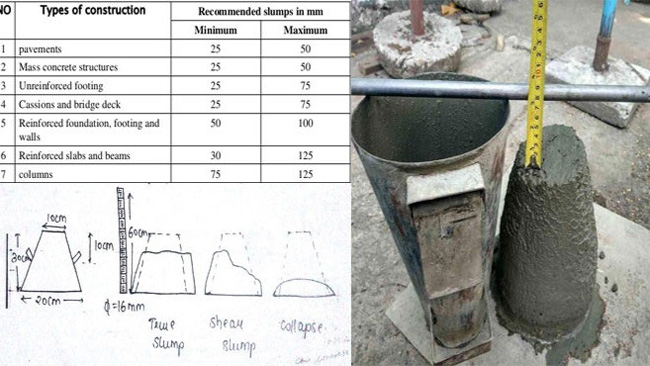

The concrete slump test helps to measure the consistency of the fresh concrete to assess the process of how the concrete will flow. The concrete slump test also helps to assess the defects in the concrete mix, thus enabling the operators to amend the concrete mix before pouring it on the construction site.

The conduct of the slump test of the concrete can determine that if the water-cement ratio is too high in the concrete, or if the workability of the concrete is high or not. The concrete slump test helps to ensure that the batches of concrete have greater strength and quality.

Factors affecting the concrete slump test procedure

There are so many factors that influence the process of the concrete slump test. These are:

- The properties of the materials in the concrete, including the fineness of the materials, the particle size distribution of the materials, the temperature of cementitious materials, the moisture content of the concrete materials and other properties, can influence the procedure of the concrete slump test.

- The methods of concrete batching, concrete mixing and concrete transporting can also influence the concrete slump test procedure.

- The sampling technique of the concrete, the slump-testing procedure and also the conditions of the test equipment for the concrete slump test also affect the slump testing procedure of the concrete.

- The amount of water that has been used in the concrete can also impact the concrete slump test. In addition, the time for concrete mixing can also influence the concrete slump test process.

Equipment required for carrying out the concrete slump test

Slump cones

The slump cone has been made from metal which are able to resist dents and any kind of deformations. The slump cone helps to separate the models, thus helping to meet the inch or metric unit of the measuring requirements.

Base plates

The base plates are another crucial equipment for conducting the concrete slump test, which helps to make the concrete slump test procedure easy and also helps to achieve more consistent results for the concrete slump test. These ready-made base plates help to secure the slump cone’s foot tabs, which allows the free movement of the slump cone.

Sample scoops

The sample distribution has been done evenly with the help of the sample scoops. The sample scoops reduce the requirements for conducting the repeated sampling process of the concrete.

Tamping rods

There is enough length in the tamping rods, which helps to ensure accurate penetration that is required during rodding. The tamping rod also features the correct diameter for the appropriate centralisation of the sample.

Slump cone filling funnel

The slump cone filling funnel helps to fill the slump cone while minimising the amount of waste.

Measuring devices

The slump value of the concrete can be measured with the help of the measuring devices. These devices include tape measures, finer graduations or rulers.

Discuss the concrete slump test procedure

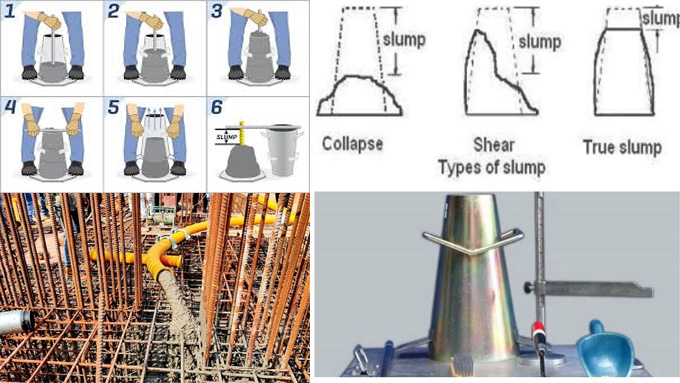

The concrete slump test has been carried out by following several steps, which are as follows:

- In the first step of the concrete slump testing procedure, the slump cones have been placed on a flat and horizontal surface and stand on the footholds. This process helps to ensure that the slump cone has been planted firmly on the ground.

- In the second step, the slump cones have been filled in three layers with the help of the steel tamping rod. This process has been done 25 times per layer.

- After filling the slump cones, the concrete that has overflowed from the top has been removed, which helps to ensure that the concrete fills the slump cone to the top level. Any concrete that is emitted has also been removed from the slump cone’s base.

- In the next step, the slump cone is lifted vertically in a slow and steady motion. After that, the slump cone has been placed upside down on the surface.

- In the next step, the steel rod has been placed across the top of the upturned slump cone, which helps to overhang the concrete.

- In the next step, the slump level was measured to 5 mm.

Benefits of conducting a concrete slump test

There are several benefits of conducting the concrete slump test, which are:

- The concrete slump test is easy to conduct, so a non-technical person can also conduct this test.

- The concrete slump test makes it easy to check the variations in the materials that will be fed into the concrete mixer. The extremely high or extremely low slump helps to indicate the undesirable workability of the concrete.

- The conduct of the concrete slump test is cost-effective as this test can be conducted at the construction site, and there is no need to send a sample of the concrete to the laboratory.

- A long period is not required for conducting the slump test.