NEWS | SOFTWARE | SHEET

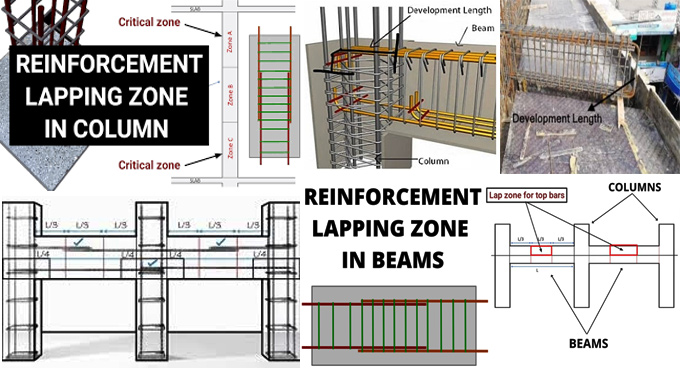

Reinforcement Lapping Zone in Beam and Column

The lapping length refers to the length of overlap among the two reinforced bars that have been used for constructing columns. The reinforcement lapping has been done to ensure the continuity of the reinforcement. This also helps to provide enough strength to the structural elements. The reinforcement lapping length is crucial for the reinforced concrete structure to ensure that the structural loads are transferred and distributed effectively.

Factors that impact the lapping length

There are several structures that impact the reinforcement lapping length, which are as follows:

The concrete grade

The lapping length has been influenced by the strength of the concrete.

Diameter of the bar

In the case of the longer lapping length, the thicker rebars have been required.

The structural design

The lapping length has also been influenced by the design specifications given by the structural engineers.

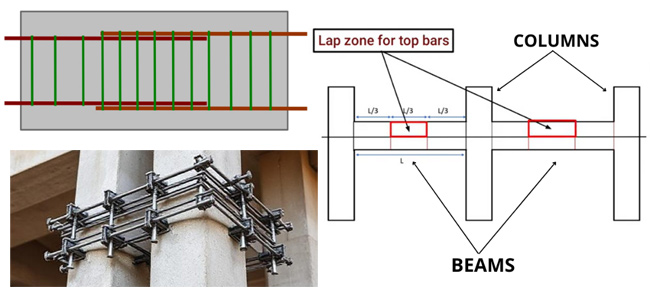

Reinforcement Lapping Zone for Beams

It needs to identify the points at which a member has been subjected to the maximum bending moment before deciding the lapping zones of the beams. The tension zone of the beams also needs to be identified. The beam has the tendency to bend in a way where the maximum bending moment is generated at the center of the span. The positive moments are present at the center of the span, whereas the negative bending moments are present at each support of the beam. Because of the maximum bending moment, the maximum tension has been experienced by the top fiber of the beam at each end and the bottom fiber in the mid-span. So, these are also known as the tension zones of the beam.

The overlapping of the bars in the tension zones of the beam can not be done, as the reinforcement of the bars can come out of the concrete because of the maximum stress. In the case of the bottom bars, the bars can not also be overlapped at the mid-span of the beam because there is the maximum tension at the bottom fiber of the beam. Whereas, the top bars of the beams can be overlapped in the mid-span of the beam because there is minimum tension at the top fiber of the mid-span of the beams.

In the case of dividing the span of the beam into three equal parts, in the intermediate zone, the overlapping can be done. In this case, each bar needs to be overlapped at alternative levels in the lapping zones of the beams. On the other hand, the bottom bars need to be overlapped at column junctions and have to be overlapped at alternative levels in the lapping zones of the beams.

Reinforcement Lapping Zone in the Column

The reinforcement lapping zone in the columns helps to keep the steel bars connected, as a result, the structural load can be transferred from one steel bar to another effectively. In the case of the columns, it has been divided into three zones, which are Zone A, Zone B, and Zone C. Among these three zones, Zone A and Zone C have been considered as one of the critical zones as compared to Zone B. These two zones are subjected to the maximum bending moment as compared to Zone B due to the lateral loads, including wind loads and seismic loads, which makes these two zones more critical.

In the case where of load has been applied in Zone A, it bends the column in such a way that the maximum moment is generated at Zone C. In the case where of load has been applied at Zone B, the end zones have experienced the maximum bending moment as compared to the intermediate zone. On the other hand, in the case of the load has been applied in Zone C, the maximum bending moment has been generated at Zone A of the column. Among these three cases, the end zones have experienced the maximum bending moment. This means this will not be safe to overlap the reinforcement bars in the critical zone. The overlapping should be provided at the intermediate zone in which the bending moment is minimum.

Effectiveness of the proper Lapping in the Columns

Proper lapping should be ensured in the reinforced columns because of their several important functions, which are:

The structural strength maintenance

The reinforcement lapping helps to ensure that the steel bars act together to resist bending forces and shear forces. This helps to increase the overall strength of the reinforced column.

Prevent cracks or failures

In the case of incorrect lapping, there will be weak points in the construction structure, which enhances the risk of cracks in the construction structure or also leads to structural failure under load.

Marinating safety standards

The proper lapping process also helps to ensure that the building standards and regulations have been met properly, which is crucial for meeting the safety standards of the construction projects.