NEWS | SOFTWARE | SHEET

Mastering AAC Block Masonry: A Comprehensive Guide to Laying Procedures

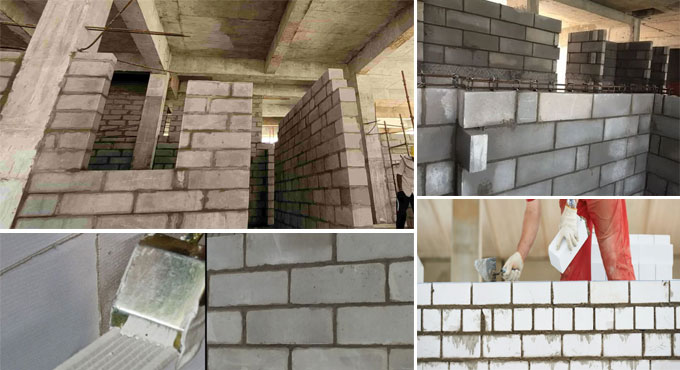

Autoclaved Aerated Concrete (AAC) has emerged as a popular building material in the construction industry due to its lightweight nature, excellent thermal insulation, and environmental sustainability. AAC blocks have revolutionized masonry work, offering builders and architects a versatile alternative to traditional construction materials.

Before delving into the laying procedure, it's crucial to understand the characteristics and benefits of AAC blocks. AAC is a lightweight, precast concrete building material containing up to 80% air.

The blocks are produced by mixing cement, lime, sand, and aluminum powder, which undergoes a reaction resulting in the formation of hydrogen gas. This process creates a porous structure within the block, contributing to its lightweight and insulating properties.

Benefits of AAC Blocks

- Lightweight: Significantly lighter than traditional concrete blocks, making them easier to handle and transport.

- Thermal Insulation: Excellent thermal properties, contributing to energy efficiency in buildings.

- Fire Resistant: Offers high resistance to fire due to its inorganic composition.

- Environmentally Friendly: Uses less material and energy during manufacturing, reducing environmental impact.

- Versatility: AAC blocks come in various sizes and can be easily cut and shaped, offering flexibility in design.

Procedure for Laying AAC Block Masonry

The successful implementation of AAC block masonry involves a systematic process that ensures structural integrity, thermal efficiency, and overall durability. Here's a step-by-step guide on how to lay AAC blocks:

1. Foundation Preparation:

The foundation serves as the base for the entire structure, providing stability and load-bearing support. Follow these steps for a robust foundation:

- Ecavation: Dig the foundation trench to the required depth and dimensions, ensuring it is free from debris and loose soil.

- Compaction: Compact the soil at the bottom of the trench to achieve a stable base for the foundation.

- PCC Bedding: Lay a plain cement concrete (PCC) bedding on the compacted soil to create a level surface for the AAC blocks.

2. Layout and Marking:

Accurate layout and marking are essential for maintaining alignment and precision in AAC block masonry. Follow these steps:

- Setting Out: Use a string line and pegs to set out the corners and edges of the wall, ensuring accurate dimensions.

- Marking Levels: Establish reference levels for the wall, marking them on the string line to guide the masonry work.

3. Mortar Mixing:

The mortar used for laying AAC blocks plays a crucial role in the structural integrity of the wall.

Follow these guidelines for preparing the mortar:

- Ingredients: Mix cement, sand, and water in the right proportions to achieve a workable and adhesive mortar.

- Consistency: Aim for a consistency that allows easy spreading and bonding between the blocks.

- Admixtures: Consider using AAC block adhesive or additives to enhance the mortar's properties, such as water retention and workability.

4. Block Installation:

With the foundation prepared and mortar ready, it's time to start laying the AAC blocks. Follow these steps for proper block installation:

- Wetting Blocks: Before laying, wet the AAC blocks to improve mortar adhesion.

- Applying Mortar Bed: Spread a layer of mortar on the PCC bedding where the first course of blocks will be placed.

- Leveling: Place the AAC blocks on the mortar bed, ensuring they are level and aligned with the reference marks.

- Buttering Joints: Apply mortar on the vertical and horizontal joints of the blocks using a trowel, ensuring a uniform layer for optimal bonding.

- Vertical Reinforcement: Depending on the structural requirements, insert vertical reinforcement bars or mesh at specified intervals to enhance the wall's strength.

- Horizontal Reinforcement: Incorporate horizontal reinforcement at the bond beam levels, typically using a mortar-filled cavity within the blocks.

- Curing: Allow the mortar to cure for the recommended duration, ensuring proper bonding and strength development.

5. Lintel Installation:

Lintels provide structural support above openings such as doors and windows. Follow these steps for proper lintel installation:

- Reinforcement: Place the required reinforcement bars within the lintel level, ensuring they are adequately supported by the AAC blocks.

- Mortar Application: Apply mortar on the top surface of the AAC blocks where the lintel will be installed.

- Lintel Placement: Place the lintel, ensuring it is level and properly supported by the adjacent blocks.

- Joint Filling: Fill the joints around the lintel with mortar to create a secure and stable connection.

6. Wall Finishing:

Once the AAC block masonry is complete, attention turns to finishing touches to enhance both aesthetics and functionality:

- Surface Smoothing: Use a thin layer of mortar to smooth the surfaces of the AAC block wall, preparing it for further finishes.

- Rendering: Apply a layer of cement or polymer-based render for a more refined and uniform appearance.

- Painting or Cladding: Depending on the design preferences, paint the walls or apply cladding materials to achieve the desired aesthetic.

To get more details, go through the following video tutorial.

Lecturer: Engineering Motive

7. Quality Checks:

Regular quality checks during and after the AAC block masonry process are essential to ensure compliance with construction standards and specifications:

- Alignment and Plumb: Verify the alignment and plumb of the walls at various stages of construction to maintain structural integrity.

- Joint Thickness: Ensure uniform thickness of mortar joints to guarantee proper bonding between blocks.

- Level and Dimensions: Regularly check the level and dimensions of the walls to avoid deviations from the intended design.

- Reinforcement Placement: Confirm the correct placement of vertical and horizontal reinforcements to meet structural requirements.

8. Thermal Insulation Considerations:

One of the key advantages of AAC blocks is their excellent thermal insulation properties. To maximize these benefits, consider the following:

- AAC Block Thickness: Choose the appropriate thickness of AAC blocks to achieve the desired insulation value.

- Sealing Joints: Pay special attention to sealing joints between blocks to minimize thermal bridging and air infiltration.

- Additional Insulation: In regions with extreme climate conditions, consider incorporating additional insulation layers or materials to enhance thermal performance.

Mastering the procedure for laying AAC block masonry is essential for architects, builders, and construction professionals seeking to harness the full potential of this innovative building material.