NEWS | SOFTWARE | SHEET

Bar Bending Schedule of a Floor Column in Construction: A Comprehensive Guide

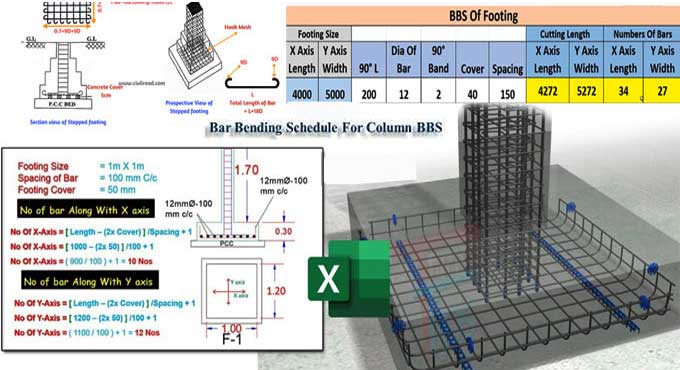

In the realm of construction, a crucial aspect of any reinforced concrete structure is the proper design and implementation of the reinforcement bars, commonly known as rebars. A well-executed Bar Bending Schedule (BBS) is fundamental for the successful construction of floor columns, ensuring their strength, stability, and longevity.

This article aims to delve into the intricacies of the Bar Bending Schedule for floor columns, discussing its significance, preparation, and application in construction projects.

What is Bar Bending Schedule?

Before we dive into the specifics of floor column BBS, it is essential to understand the concept of a Bar Bending Schedule. The Bar Bending Schedule is a detailed document that provides information about the reinforcement bars, their shapes, sizes, and quantities required in a particular reinforced concrete structure. It is based on the structural drawings and engineering calculations and plays a pivotal role in ensuring the structural integrity of the building.

Importance of Bar Bending Schedule for Floor Columns

Floor columns bear the weight of the entire structure and transfer the loads from the floors above to the foundation below. Ensuring the correct BBS for floor columns is essential for several reasons:

1. Structural Integrity: A well-prepared BBS ensures that the floor column can withstand the applied loads and maintain structural integrity, preventing any untoward incidents. The proper placement and arrangement of the reinforcement bars, as specified in the BBS, contribute significantly to the overall stability of the structure.

2. Material Optimization: Accurate BBS minimizes the wastage of reinforcement materials, saving both costs and resources during construction. It allows engineers to calculate precisely the amount of steel required for the floor column, avoiding unnecessary excess or shortages.

3. Quality Control: The BBS acts as a reference guide for the construction team, aiding in maintaining quality standards and avoiding errors during reinforcement placement. It provides clear instructions and specifications for the bending and positioning of each bar, ensuring uniformity and consistency in construction.

4. Smooth Execution: With clear instructions provided in the BBS, the construction process becomes streamlined, reducing the chances of on-site confusion. Construction teams can work efficiently, with a well-defined plan in place, leading to a smoother construction process.

5. Compliance with Codes and Standards: BBS ensures compliance with local building codes and industry standards, guaranteeing a safe and reliable structure. It ensures that the design and construction of the floor column align with the regulations set forth by relevant authorities.

Components of a Bar Bending Schedule

A typical Bar Bending Schedule for a floor column comprises the following components:

1. Column Details: This section includes information such as the column number, floor level, and dimensions (length, width, and height). These details provide a comprehensive understanding of the column's location and purpose within the structure.

2. Reinforcement Bar Details: It specifies the type, diameter, and grade of reinforcement bars used in the column. This information is crucial for ensuring that the appropriate quality and strength of steel are used in the construction.

3. Bend Shapes and Dimensions: This section provides details about the shapes and dimensions of the bends required in the reinforcement bars. Properly designed bends are essential for achieving the required bond strength and anchorage of the bars in the concrete.

4. Bar Marking: Each reinforcement bar is assigned a unique mark for identification and placement on the construction site. Bar markings aid in identifying individual bars and ensuring their correct placement as per the BBS.

5. Quantity of Bars: The number of bars required for each size and shape is listed, enabling accurate estimation of material quantities. This information is vital for procurement and inventory management during construction.

6. Bar Lengths: This section specifies the lengths of each reinforcement bar used in the column. Accurate bar lengths are critical for proper installation and to ensure that the bars extend to the required development length.

7. Total Weight of Reinforcement: The cumulative weight of all the reinforcement bars required for the column is mentioned. This information helps in determining the total amount of steel needed for the entire construction project.

Preparation of Bar Bending Schedule for Floor Columns

The preparation of a BBS for floor columns involves several crucial steps. Let's explore each step in detail:

1. Structural Analysis: Before starting the BBS, a comprehensive structural analysis of the floor column is conducted. This analysis helps determine the loads the column will bear, ensuring the correct selection of reinforcement bars based on the anticipated stresses.

2. Structural Drawings: Detailed structural drawings, including plans, elevations, and sections, are prepared, highlighting the dimensions and positions of the floor columns. These drawings serve as the foundation for creating an accurate BBS.

3. Bar Selection: Based on the structural analysis and drawings, the appropriate type, diameter, and grade of reinforcement bars are chosen. The selection of the right bars ensures that the column can handle the imposed loads and perform optimally.

4. Calculation of Bar Lengths: The required lengths of the reinforcement bars are calculated, taking into account the column height and any overlapping requirements. Proper calculation of bar lengths ensures that each bar is long enough to develop its full strength within the concrete.

5. Bend Shapes and Dimensions: The bend shapes and dimensions are designed based on engineering specifications to ensure adequate anchorage and development length. Properly shaped and dimensioned bends are crucial for the bars to transfer forces effectively between the concrete and steel.

6. Bar Marking: Each reinforcement bar is marked with a unique identifier to avoid confusion during construction. Bar marking ensures that each bar is placed in its designated position and orientation, according to the BBS.

7. Quantity Estimation: The quantities of reinforcement bars required for the floor column are estimated, considering the bar lengths, bend shapes, and numbers. Accurate quantity estimation helps in efficient material planning and cost control.

8. Compiling the BBS: All the gathered information is compiled into a systematic BBS format, including column details, reinforcement bar details, bend shapes, bar marking, quantities, and total weight. The comprehensive BBS serves as a comprehensive guide for the construction team during the execution of the project.

Application of Bar Bending Schedule for Floor Columns

Once the BBS for the floor columns is ready, it serves as an invaluable tool during the construction process. Some key aspects of its application include:

1. Communication and Collaboration: The BBS acts as a bridge of communication between the structural engineer, site engineer, and the construction team. It ensures that everyone is on the same page regarding the reinforcement requirements. The BBS serves as a common reference point for all stakeholders involved in the construction project.

2. Quality Assurance: The BBS aids in maintaining the quality of construction by providing precise instructions for the placement of reinforcement bars, their bending, and overlapping. Following the BBS ensures that the reinforcement is correctly positioned as per the design, avoiding errors and potential weak points in the structure.

To get more details, go through the following video tutorial.

Lecturer: Learning Civil Technology

3. Material Management: With accurate quantities mentioned in the BBS, construction teams can efficiently manage the procurement and usage of reinforcement materials, reducing wastage and costs. Proper material management is essential for optimizing construction resources and adhering to project budgets.

4. On-Site Guidance: The bar markings on the reinforcement bars allow the construction team to place each bar accurately at its designated location. The bar markings serve as visual aids for the construction team, ensuring the correct placement of bars as per the BBS.

5. Adherence to Codes and Standards: Following the BBS ensures compliance with the specified building codes and standards, ensuring a safe and durable floor column. Building codes and standards are established to ensure the safety and reliability of structures, and adherence to the BBS guarantees that these requirements are met.

A well-prepared Bar Bending Schedule is indispensable for the successful construction of floor columns. It ensures the structural integrity of the building, optimal utilization of resources, and adherence to safety standards. By providing precise instructions for the placement and bending of reinforcement bars, the BBS streamlines the construction process, reducing errors and confusion on-site.

As technology and construction practices advance, computer-aided software and Building Information Modeling (BIM) are increasingly utilized to generate accurate BBS. Nevertheless, the fundamental principles and components of a BBS remain unchanged, serving as a cornerstone of robust construction practices.

Emphasizing the significance of BBS in construction projects, engineers and construction professionals ensure that the structures they create stand strong for generations to come. Proper implementation of BBS leads to safe, durable, and aesthetically pleasing floor columns, reinforcing the foundation of the built environment.