NEWS | SOFTWARE | SHEET

External Plastering Work Checklist - to follow in Building Construction

The outside plastering work/task in a building assignment/project is a significant task for the reason that it offers the building’s external finish. Moreover, it’s the foundation with regard to the building’s appearance/aesthetics. As a result, all constructors must consider certain fundamental measures so as to conduct it correctly. Therefore, the subsequent checklist could be quite useful in outside plastering work/task in building construction.

A. Clean up the surface: Ensure that the building’s outside surface is cleaned up/clean. This indicates the brick or block masonry as well as concrete surface.

Those must be free of/clear of oil grease, dust, mortar dropping, loose materials, metal strips, wood, nails, and so forth. One must have a level, even surface to operate on. If not, the bonding is not going to function.

B. Create scaffoldings: One has to raise/erect/make a scaffolding so as to get to the whole exterior surface. However, one may need a double scaffolding too. One has to conduct that devoid of creating a hole within/in the wall. As, in that period, one should not affect the wall at all. On the other hand, in case authorities allow, one can obtain support from the building’s additional parts.

C. Mortar as well as socketing: The openings amid the masonry as well as the beams that exhibit on the outside have to be filled up with rich mortar. Furthermore, one has to complete the socketing tasks/works.

D. Chicken mesh: Subsequently, set/fix/install a chicken mesh on/at the joint of RCC as well as masonry wall. Furthermore, the mesh must be six inches wide. Attach/Nail that mesh at 230 mm spaces/intervals simply.

E. Plumb measure: Utilize the plumb (even the line) from top/high point to base to assure the plastering’s correctness/accurateness.

The plastering at this point must be of a one/single coat of 10 -12 mm simply. Furthermore, one should verify the entire edges.

F. Take care of jutting out things: At times, a column or a beam, or construction’s additional parts could be moving out of the plastering. Furthermore, in that instance, initially obtain permission of the designer to find out in case one can separate it.

In case one can, in that case utilize a hammer or sharp chisel to separate the jutting out/jutting-out part. Furthermore, one can utilize a concrete breaker in that. Make sure to be careful that it does not damage the building’s different part.

G. Verify features: Conduct a comprehensive verification to find out in case the building’s entire features on the exterior are exhibiting all right.

Those might comprise elevation/elevational characteristics/features as well as windows as well as doors, and so forth. The finished/completed work must echo/reverberate the plans/architectural drawings.

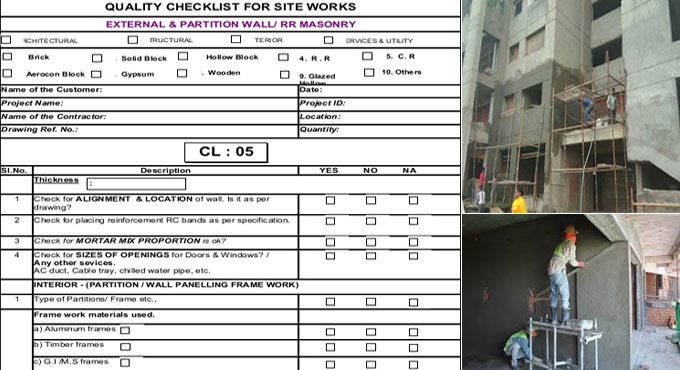

Download checklist for site works

H. Dampen/Wet the surface: Once it’s checked that the entire masonry work has completed, wet the outside surface. That must be carried out 1 or 2 days before plastering.

I. Create the mix: Filter/Sieve as well as wash/wash up the sand correctly in order that it does not possess silt content above eight %. Subsequently, obtain 1:5 ratio as well as mix up in the machine. Go on to simplify that procedure in order that the mixed mortar could be set/placed in half an hour.

J. Put on/Apply initial coat: Begin plastering. Furthermore, the initial coat must not be above 10 - 12 mm thick. Furthermore, there should not be non-uniform surfaces. One has to wait five days with regard to the initial coat to set right/cure.

K. Put on/Set next coat: Utilize wires to form the initial coat surface non-uniform earlier than putting on/applying the subsequent/second coat. That is going to form improved association/bonding. That coat must be 6 – 10 mm thick simply. Await seven days with regard to the second coat setting/curing.