NEWS | SOFTWARE | SHEET

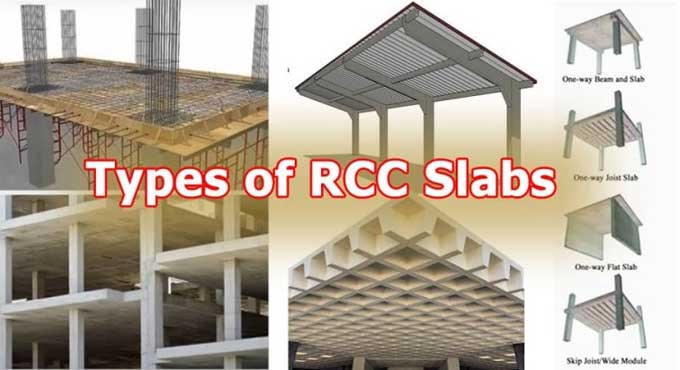

How will various Types of RCC Slabs be used in Construction in 2023?

A reinforced concrete slab provides flat surfaces in buildings and is a crucial structural element. One way slabs and two way slabs are generally classified based on the reinforcement, beam support, and span ratio. Two sides support the former, and the ratio of long to short span exceeds two. Its long to short distance ratio is smaller than two, but it is supported on four sides.

One Way Flat Slab

For heavy loads, one way flat slabs are constructed with 4 to 6 inches of concrete. The support structure is the name given to this slab. This product is designed for applications where one direction needs support & the other requires less support.

Commercial or residential projects can benefit from this slab type because it is affordable and simple. In particular, a ground level structure can benefit from its affordability. There is a significant limitation to one way flat slabs due to their limited span capability. Many bridges and ceilings cannot be installed with them because of this.

Two Way Flat Slab

All four corners of a two way construction are supported by beams for equal weight distribution. Multi storey buildings typically use this type when additional floors need to support the weight. Review the breadth and width of a specific project to determine the type you need. You should choose a one way slab if one direction is longer than the other by a ratio of two to one.

Sun Shade Slab

Concrete slabs that slope upwards over doors or windows are called sun shade slabs. In order to protect a door or window from direct sunlight and rain, this specialized structural piece must be used. When it is fully cured, it is installed on the exterior of a building after being poured separately.

Consider using a sun shade slab instead of a steel or fabric shade. Due to their non structural nature, sun shade slabs do not need to be particularly thick. The goal should be for them to be thick enough to support their own weight. For better safety, ensure the slab above a window or door is properly secured.

Cable Suspension Slab

Bridges are among the most common construction sites for cable suspension slabs. The concrete surface can be stretched without compromising its structural integrity. Floating foundations or raised walkways between buildings can also be constructed using this type of slab in commercial construction.

Suspension cables are sized and frequency based on many critical factors. Depending on the weight, length, and load the slab will be suspended under, you'll need to calculate its weight, length, and load. When designing columns to support a bridge or other structure, you can take into account these factors to arrive at optimal slab dimensions and suspension considerations.

Projected Slab

Projected slabs are often used as part of covered drop-off entrances, since they are connected to buildings on one end and hang freely on the other.

Direct sunlight and inclement weather are protected from vehicles and pedestrians. In a cantilever design, the slab has an end which is supported safely from the other end, thus balancing the weight.

Hollow Core Slab

This unique process reduces the labor and time required for your project by pre-pouring and delivering slabs to the job site. You can easily lift & install hollow core slabs on supporting columns while using a crane. The span distance of hollow core slabs is superior to that of other slab options. Additionally, they have holes through them that make it easy to install wiring and plumbing, thus reducing construction time and cost.

Choose a reputable contractor when ordering hollow core slabs. These slabs may be damaged by casting errors or improper transportation, which quickly turns into a time-consuming and expensive problem.

Pre Tension Slab

Reinforce your concrete slab with steel cables that are tightened. The purpose of a pre-tension slab is the same as that of a post-tension slab; it is to prevent compression and to improve overall strength. High tensile steel cables are used to accomplish this. Concrete is poured into the framework using hydraulic jacks that create tension in the system.

A crack in the structure is prevented from separating the concrete pieces by the tension of the cables. Thinner products can be made by using pre-tensioned slabs. The thickness of concrete required for pretension and post-tension slabs is lower than for other reinforced slabs. It also reduces the need for joints because of the tension in the slab. There are some structures in which the slab does not have any joints at all.

Post Tension Slab

Post-tension slabs are similar to pre-tension slabs in terms of their characteristics. Its lightweight, durable results can be achieved by tightening cables after the concrete is poured. Inexperienced concrete workers may leave air pockets in the slab. A sudden slab failure can result from corrosion of the steel cables in these pockets.

To get more details, go through the following video tutorial.

Lecturer: Civil Engineering

Sunken Slab

It is necessary to build a slab that is below the floor grade and accommodates water and sewer lines during these construction situations. There is a slope to a sunken slab and the floor is below grade, thus allowing the top of a shower base or other fixture to be flush with the surface. Determine the size of the recess required to accommodate the slab and fixture using a construction level.

Kitchen Slab

In residential construction projects, this type of slab is used for kitchen platforms. It is a common way to place a stove on a fire proof surface. It is not designed for structural purposes, but can be used for cooking appliances and ovens.