NEWS | SOFTWARE | SHEET

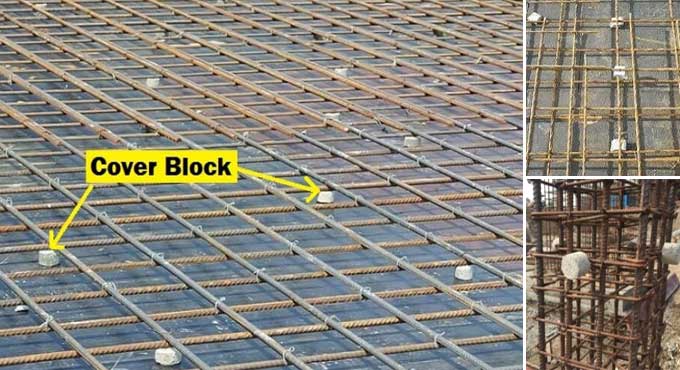

Cover blocks: why they are used in Reinforcement and what they do

This term refers to the distance between the surface of a concrete slab and the outermost layer of reinforcement. In general, a concrete cover block acts as a spacer to elevate the rebar matrix so that concrete can flow below it. To prevent corrosion, it must be totally covered with concrete. Usually, it needs about 2 to 3 inches of concrete on all sides.

For all RCC structures such as slabs, columns, beams, footings, etc., concrete cover blocks or concrete spacer blocks provide the necessary covers or spacing for reinforcement bars from the formwork. There are numerous shapes and sizes to choose from depending on their usage.

Purpose of Concrete Cover

The purpose of a concrete cover is to prevent damage to a building part, not to serve as a structural component. If the concrete cover is insufficient, it can flake off, exposing the steel to the external air. The concrete should encase the steel on all sides to prevent exposure to the outside air. As a result, the steel may corrode since it is no longer protected.

Types of Cover Block

Concrete Cover Block: Those cover blocks, which are made up of cement concrete that is measured in designed proportions, are known as concrete cover blocks.

Production: In construction sites, concrete blocks should be stronger than concrete made with RCC members. A cover block can be bought on the market for a very low price.

Unfortunately, cover blocks are not always available on the market. In such a situation, construction cannot continue without a clear cover.

Cover blocks can be made on site from materials readily available on construction sites. A cement mortar ratio of 1:1 or 1:2 is usually used to make concrete blocks.

Application

- The material is used in the construction of slab covers.

- It is used in the bottom of beams.

- In the end of a rebar, it is used.

- Foundation footings and pilings are constructed with it.

PVC Cover Block: In the decoration field, polypropylene & PVC cover blocks are commonly used to make cover blocks, which are made up of fabrication of those materials.

Application

- It is used in the bottom of beams.

- At the end of the rebar, it is used.

- Foundation footings and pilings are constructed using it.

- It is used in RCC columns where more coverage is required.

Merits of Cover Block

- To maintain the required gap between the Rebar and concrete surface, the cover block must be maintained.

- It is caused as a result of the concrete not being able to properly adjust and flow underneath the rebar.

- Reinforcements are given the proper strength as a result of it.

- Corrosion of the rebar is prevented.

- This reinforces the rebar to make it better resistant to fire and moisture.

Why Concrete Cover Block is needed in Rebar?

RCC structures usually have rebar cover concrete ranging from 15 mm to 50 mm thick. It may go up to 100 mm in heavy infrastructure and harsh environmental conditions.

To get more details, watch the following video tutorial.

Lecturer: Civil Engineer Sameer Nayak

Concrete Cover Block Spacing Distance

RCC structure type, the diameter of rebar, and rebar direction determine the distance between two cover blocks.

With increasing bar diameters, there will be less sagging; as a result, fewer cover blocks are required.