NEWS | SOFTWARE | SHEET

How to Estimate Slump Cone Volume in a Quantity Survey

Slump tests are crucial in civil engineering as well as in the construction world. Slump tests calculate the consistency of brand new concrete before setting in a particular batch.

A concrete slump test can be defined as the difference between the heights of the concrete before the slump cone or mold is removed and the height of the concrete after the slump cone is removed, as measured during the slump test of the concrete.

Purpose of the Slump Test

The purpose of this test is to verify the consistency of the concrete after it has been formed. Concrete consistency refers to the ease with which it pours. Wetness is specified by this parameter. Concrete's adaptability is influenced by its consistency.

Using these easy to follow processes, one can calculate the volume of a slump test mold. A surface is created on the upper part of the mold for the circle, which has a diameter of 100 mm and a diameter of 200 mm on the bottom.

R represents the radius of the top surface of the mold and the radius of the bottom surface where a height is represented by the letter h.

Types of Slump

Shear Slump: In an inclined plane, one half of the cone slides down, known as a shear slump. Performing the experiment again to avoid shear slump will indicate a lack of cohesion of the mix.

Zero Slump: A concrete that keeps the actual shape of the mould is known as zero slump concrete, which means it is stiff, consistent, and almost impossible to work with.

Collapse Slump: It has been observed that fresh concrete collapses completely in this particular case. Slump tests should not be performed on wet or high workability mixes because they are not suitable for slump tests.

True Slump: Having a high stiff consistency, the mix is very workable. For the most part, concrete in a true slump will subside in a short time and more or less maintain the shape of the mould. Ideally, it would be desirable for the slump to be of this type.

Apparatus of Volume of Slump Test

In order to conduct a slump test, the apparatus consists of at least one metallic mould that has the shape of a cone frustum and has the internal dimensions that are given below.

It is essential to understand that the apparatus for conducting the slump test consists essentially of a metallic mould shaped like the frustum of a cone which has the following internal dimensions.

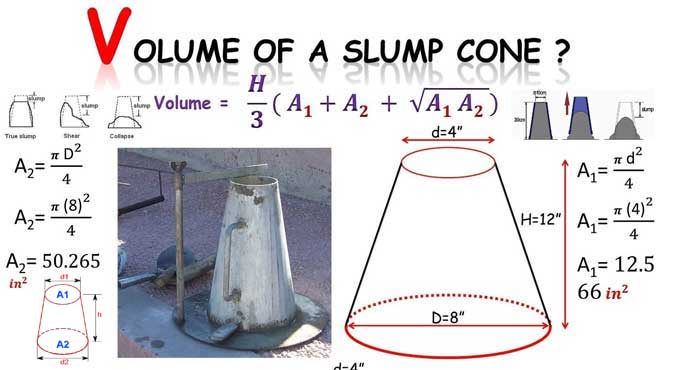

Volume of Slump Cone Calculation

There are many methods used to measure the consistency of concrete. Still, the Slump Test is the most popular method because it can be done in the laboratory or on the construction site very quickly as well.

There is no need to use this method if the concrete is too wet or too dry. Several factors contribute to the workability of concrete. But this test doesn't always measure all of them, nor does it always reflect their concrete place ability.

Although this is used only as a control test, it indicates the uniformity of the concrete batch to batch.

Volume of Frustum

πh(R² + Rr + r²) / 3

Top Diameter = 20 cm

Height = 60 cm

Bottom Diameter = 40 cm

To get more details, watch the following video tutorial.

Lecturer: Engineer Boy

= 3.14 x 0.6 (0.2² + 0.2 x 0.1 + 0.1²) / 3

= 0.04396 cubic meter

It can be calculated easily in this way for a Slump Test on the site.

Recommended Articles:

Concrete Slump Analysis – Testing Method

How to do a Concrete Slump Test