NEWS | SOFTWARE | SHEET

Everything you need to know about the Batching of Concrete

Concrete batching is the process of weighing the ingredients needed to manufacture concrete, including cement, sand, aggregates, printed circuit board waste or alternatives and water, to guarantee proper mixing in line with the mix ratio.

The right quantity of each element must be utilized to produce high-quality concrete. Concrete batching is a technique for estimating the number of components needed to produce concrete.

For cement, aggregates, and water, accuracy should be within 3% of the batch quantity; for admixtures, accuracy should be within 5% of the batch quantity. Weight batching and volume batching are the two commonly used methods for mixing concrete.

The size of the project and the necessary requirements are the only factors that affect the batching technique. However, the weight-batching strategy is often used and is strongly suggested.

Factors of Batching of Concrete

Below mentioned some of the factors affecting concrete batching:

- A batching technique for concrete will be selected based on how much work has to be done with the approach.

- Depending on how much concrete has to be produced each day or each hour, several batching techniques are used.

- The accuracy of weight measurement is based on batch performance standards.

- Either mechanical or electronic batch weighers are possible.

- Despite being less prevalent than electronic weight batches nowadays, some industries still use mechanical weight batches as a backup for electronic weight batches.

- There are several different types of electronic batch weighers. Depending on the kind of plant, weight batches should be used in high-silos, low-profile, or subterranean batch plants. The batches might be stationary ones that weigh persons standing still or non-stationary ones that weigh transportable goods.

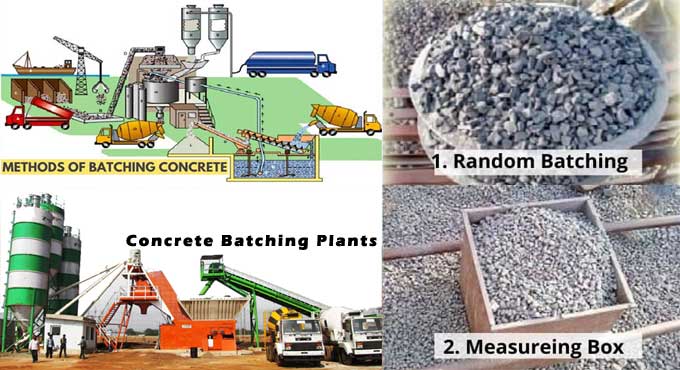

Various Batching Methods

Batching concrete can be done in two different ways those are as follows:

Concrete batching by volume

For the manufacture of concrete in modest building projects, volumetric batching is frequently used. Each component of concrete is measured by its loose volume during this batching procedure.

To measure them, a gauge box is utilized, which is specialized machinery. To make calculating the top level simpler, the gauge or measuring boxes have been made much deeper with a thin top surface.

Regardless of the batching technique, cement is always measured by weight. If volume batching is used, the effect of fine aggregate bulking should be updated because water is measured in liters and has a density that is measured in kilograms per liter.

Concrete batching by weight

The weigh-batching method for cement concrete is used in all significant projects. Weigh-batches are available in a wide range of sizes and forms. Manual batching is utilized for smaller tasks.

The mixture and total weight of the materials are done by hand. Additionally, ordinary platform weighing machines can be used for weighing. Equipment with weigh buckets is utilized for large projects. The ingredients are fed into the weigh buckets by hoppers, which then feed the mixer by gravity.

The weight of each individual item that is provided to each batch is visually recorded by some of the most sophisticated batches. Gradually graduated buckets are not used in weight batching because the water may leak.

With the mixer's design, any quantity of water can be accommodated by its tank, which can be vertical or horizontal.

Difference of Batching of Concrete

- Given that granular materials' voids make it difficult to calculate their exact volumes, weight batching is a more accurate method of batching than volume batching.

- Before batching, the moisture content and presence of the aggregate should be taken into account. Under the case of fully automated weigh batching, it is conceivable, however, volume batching is not suitable in these conditions.

- When concrete is mixed by weight rather than volume, it has a greater compressive strength after 7 and 28 days.

- For the same mix percentage, volume batching creates a slump that ranges from low to high, whereas weight batching gives a slump that is medium to very high.

- Volume batching doesn't require specialized labor, but weight batching does.

- The batching technique utilized depends on the project's size and the rate of concrete production.