NEWS | SOFTWARE | SHEET

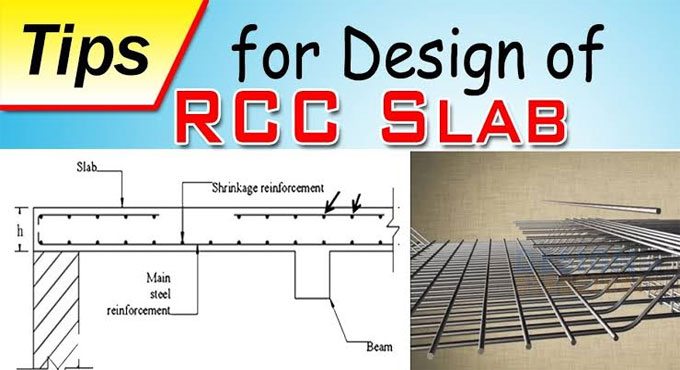

Useful Tips for Design of RCC Slab

Subsequent are the RCC Slab Design as well as Detailing instructions. Reinforced Concrete Slab Arrangement/Design Instructions.

A. Efficient/Effective slab span - Efficient/Effective slab span must be lower of the 2

L = d [effective depth] plus clear span

L = Centre to centre distance amid the support

B. Slab Depth: The slab depth relies on/depends upon bending moment as well as deflection principle. The trail depth could be found utilizing

- Effective depth, d = Span/[modification factor x [L/d]Basic]

- For getting modification factor, the steel percentage for slab could be supposed from 0.2 to 0.5 percent.

- The effective depth, d of 2 way slabs could even be supposed utilizing cl.24.1, IS 456 offered short span is less than 3.5 m as well as loading class is less than 3.5 KN/m2

| Support Type | Fe-250 | Fe-415 |

|---|---|---|

| Simply supported | L/thirty five | L/twenty eight |

| Continuous support | L/forty | L/thirty two |

Otherwise, the subsequent guidelines/thumb rules could be utilized.

- 1 way slab d is equal to (L/22) to (L/28).

- 2 way simply supported slab d is equal to (L/20) to (L/30)

- 2 way restrained slab d is equal to (L/30) to (L/32)

C. Load on slab – The load on slab contains floor finish, Dead load as well as live load. Moreover, the loads are computed for each unit area [load/m2].

Dead load is equal to D x 25 kN/m2 [Wherein/Where D is slab thickness in m]

Floor finish [supposed as] is equal to 1 to 2 kN/m2. Live load [taken/ supposed as] is equal to 3 to 5 kN/m2 (as per the structure’s occupancy). Reinforced Concrete Slab’s detailing prerequisites in accordance with IS456: 2000 a- Nominal Cover

With regard to Mild exposure: 20 mm

With regard to Moderate exposure: 30 mm

On the other hand, in case the bar diameter don’t go beyond 12 mm, or cover might be decreased by five mm. Therefore, regarding/for main reinforcement equal to 12 mm diameter bar as well as regarding/for mild exposure, the nominal cover is fifteen mm.

Least reinforcement – The reinforcement in any direction in slab must not be lower than

- 0.15 % of the overall cross-sectional area with regard to Fe-250 steel.

- 0.12 % of the overall cross-sectional area with regard to Fe-415 as well as Fe-500 steel.

Bars’ Spacing - The utmost bars’ spacing must not go beyond.

- Main Steel: 300 mm or 3d either is lesser

- Distribution steel: 450 mm or 5d either is lower wherein/where ‘d’ is the slab’s effective depth. Message/Note: The bars’ least/minimum clear spacing isn’t reserved/maintained/remained lower than 75 mm (preferentially 100 mm) although code doesn’t suggest a value.

Bar’s utmost diameter - The utmost diameter of bar in slab, must not go beyond D/8, wherein D is the overall slab thickness.