NEWS | SOFTWARE | SHEET

Why is Lintel Types Important in Construction?

Despite the fact that lintels are commonly used and are relatively simple to construct, you are here to define them theoretically. Therefore, stirred steel lintels have become more and more popular.

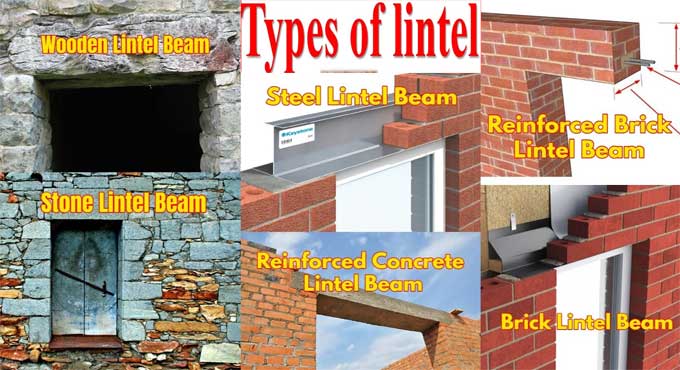

In lintel construction, different materials are used depending on cost and availability. There are six basic types of lintel beams, depending on the elements that make up their formation.

Define Lintel: When openings such as doors, windows, and so forth are necessary to provide a building structure, a lintel acts as a support for the above wall or partition material.

Lintol is the British English name for the lintel, which is an American word. There is no difference between Lintel and Lintol - they are both the same word. It is a horizontal secondary structural element that is usually found above openings for windows, doors, portals, fireplaces, etc.

Stone Lintel

A lintel can be made with rectangular bits of stone. Typically, these types of lintels are used in areas with abundant stone availability. Alternatively, two pieces of timber are added together to form the lintel when the opening is long. Due to their weight and unavailability of other materials, they are merely used in mountainous buildings.

Stone masonry structures are intrinsically bound to their use. To utilize stone lintels effectively, one must take into account the characteristic layering of these structures. Its thickness is an important design factor for the stone lintel. This sort of beam will be firm and solid, so four centimeters of thickness is a good rule of thumb per 30 cm span.

Brick Lintel

Lintels are constructed from first class bricks that are hard and well burnt. Coursed bricks can be laid horizontally over openings, bricks on the edges, or bricks on the ends. This type of lintel is used in small and light loads.

There is a range of thickness between 10 cm and 20 cm depending on the span of the brick. At end joints, bricks with frogs filled with mortar are more shear-resistant than standard blocks.

Reinforced Brick Lintel

Brick lintels are challenged by heavy loadings and longer spans. Reinforcement bars can be used to overcome these problems. Brick lintels that are reinforced provide more support than those that are not.

Lintels with reinforced bricks are 10 cm deep or multiples of 10 cm deep. As reinforcement, mild steel bars should be inserted between the adjacent bricks so there is enough space lengthwise between them.

Following the insertion of the bars, cement mortar is used to fill in the remaining gap. Vertical stirrups of 6 mm are used at every third vertical joint. The primary reinforcement consists of 8 to 10 mm bars placed at the bottom.

Steel Lintel

In situations where the superimposed loads are heavy and the opening gaps are considerable, a steel lintel beam is appropriate. Lintels made of steel are preferable when lintel depth is crucial, since reinforced concrete lintels cannot ignore their depth due to heavy loads. It consists of channel sections, rolled steel joists, or channel sections either assembled singly or in combinations of two or three.

A lintel can be a single section or a combination of several sections, depending on the requirements. It is typical for a single steel joist to be embedded in concrete or covered with stone facing to keep the same width as a wall. Tube separators hold together two or more units that are placed side by side. The process of relieving water is carried out in any event for ten days.

Timber Lintel

With the assistance of wooden separation pieces, timber lintel beams may be made of two wooden pieces to prevent as many great divisions as possible.

Lintels made of wood or timber is among the oldest types of lintels. In hilly areas where timber is accessible, they are most commonly used. Due to the significant expense and accessibility of modern materials, timber is constrained in open areas. Mild steel plates are sometimes arranged on top and bottom of timber lintels to reinforce them; these lintels are called flitched lintels.

Reinforced Concrete Lintel

Lintels made from reinforced concrete are very commonly used at present. Concrete's low malleability is overcome in this type by using reinforcement. Today's structures require these steel beams designed to carry heavy loads and span long distances. It is possible to cast RCC lintels either in situ or precast.

To get more details, go through the following video tutorial.

Lecturer: Civil gct

Lintels made of precast reinforced cement concrete are usually used for lintels with smaller spans. The Lintel width should be equal to the width of the wall. For every meter, they are kept around 8 centimeters thick. A lintel beam's depth is determined by its length and the magnitude of the load.

Lintel Properties

There is usually a masonry wall at the end of the lintel beam. The ends of the columns are sometimes where they are located. It is necessary to support lintels at both ends. The masonry supports must be extended enough to ensure that they are stressed within their allowable limits. A minimum bearing length of 100 mm would be required.

They transfer weight from masonry walls to lintels. You can keep the lintel width the same as the supporting wall width. As a compositional component, the lintel can also be utilized to enhance the design.