NEWS | SOFTWARE | SHEET

A Comparison of the Various Types of Steel in Construction

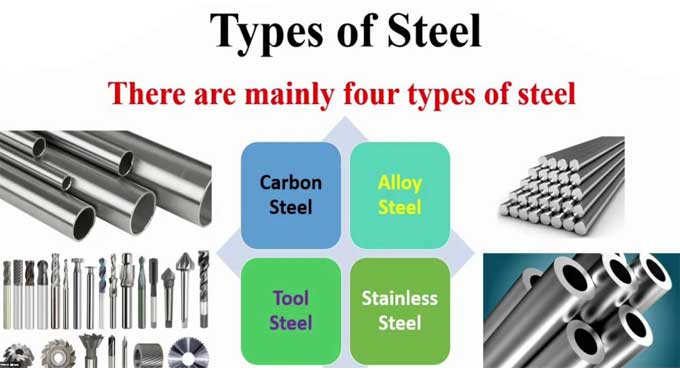

A major domestic manufacturing product is making steel. Almost anything that runs on steel, from medical equipment to cars, is made of steel. The steel materials, however, are not all the same. There are several types and alloys of steel, each with unique properties, so they are suitable for specific applications. Steel can be sturdy and heavy or ductile and flexible.

Carbon Steel

Steel alloys that contain iron, as well as carbon, are called carbon steels. However, most manufacturers define carbon steel in multiple ways.

As far as the metals market is concerned, these are both forms of carbon steel.

- Carbon-containing steel up to 2%.

- Steel contains none of the elements that consider making it an alloy, such as cobalt, nickel, tungsten, molybdenum, titanium, zirconium, vanadium, chromium, and much more.

There are steels with less than 0.4% copper and steels with magnesium/copper ratios as well, though their definitions vary by industry. Specifically, we are discussing the first two definitions.

Carbon steel can classify in three ways:

Low Carbon Steel

Carbon steels that contain up to 0.30% carbon are called carbon steels. This steel type is widely available in the metals market.

Several reasons account for this:

- Starting with low carbon steel, it is relatively inexpensive. Low carbon steel also is easy to form, especially since the carbon content is lower than medium and high steels. For instance, structural beams are perfect applications where tensile strength is not a concern.

- Another advantage of low carbon steel is that its properties can be greatly enhanced by adding other elements, like magnesium. Carburizing low carbon steel also improves case hardness while maintaining ductility and toughness.

Medium Carbon Steel

The medium carbon steel has a carbon content that varies between 0.31% and 0.60% as well as a magnesium content varying from 0.31% to 1.60%. Medium carbon steel has the advantage of being strong. There are some trade-offs associated with that.

Steel with a medium carbon content is not as ductile and tough as steel with higher carbon content, making forming and welding more difficult.

High Carbon Steel

It refers to carbon steels with carbon contents varying from 0.61% to 1.50% and magnesium levels varying from 0.31 to 0.90. Carbon steel is hard tough but high carbon steel is the best option in terms of hardness and toughness. This trade-off, however, comes with a cost. Steel with high carbon content is difficult to weld, form, or cut.

Alloy Steel

Steel alloys are the most diverse and widely available of all steel alloys. A carbon steel alloy provides unique properties to the steel by combining different alloying elements. Many alloy plates of steel are available, but the following are some of the most common:

- Chromium

- Cobalt

- Molybdenum

- Nickel

- Tungsten

- Vanadium

You can make steels with nearly all possible properties using alloy elements since alloy steels come in a wide variety. The downside is that these steels are often relatively expensive.

Stainless Steel

In comparison to carbon steel, stainless steel is usually defined by its minimum chromium concentration of 10.5%. Its unique properties come from its additional chromium content, which is found in the same proportion as carbon and iron in carbon steel. The oxidation process damages metals over time, and steel is resistant to it.

Stainless steel gleams because of chromium. In addition to cookware and knives, stainless steel is used in medical equipment.

To get more clear ideas, go through the following exclusive construction video tutorial.

Lecturer: Amazing Civil Engineering Study

Stainless Steel has 3 parts, there are

Ferritic Alloy: Ferritic stainless steel alloy is a semi-common stainless steel alloy. Due to their magnetic properties, they are better suited for magnetic applications than austenitic alloys. These alloys are more affordable because of their low nickel content.

Martensitic Alloy: The Martensitic stainless steel alloy is not as common as other stainless steel alloys. Hardness and toughness are exceptional in these alloys, but poor oxidation properties make them unsuitable for applications that require incredible hardness.

Austenitic Alloy: Austenitic stainless steels are the most widely used type of stainless steel on the market. They are non-magnetic but can become magnetic under certain conditions. They resist oxidation and provide a uniquely appealing appearance.

Tooling Steel

Lastly, we have tool steel. Tools such as drilling are made from these steels. Steels used for tooling are often made of molybdenum, vanadium, tungsten, and cobalt. These steels are tough, durable, and highly heat-resistant.

Tool steel can be classified into six grades:

- Air-hardening

- Water-hardening

- D-type

- Hot-working

- Shock-resisting types

- Oil-hardening