NEWS | SOFTWARE | SHEET

Underwater Concrete: Exploring Advantages, Disadvantages, Applications, Construction Techniques, and Essential Considerations

In the dynamic landscape of construction, where innovation meets adaptability, underwater concrete emerges as a remarkable solution. This specialized concrete type plays a pivotal role in projects that require structural integrity beneath water bodies.

Understanding Underwater Concrete

Underwater concrete, as the name suggests, refers to a specialized type of concrete designed specifically for construction projects beneath water surfaces. This type of concrete possesses unique properties that enable it to withstand the challenges posed by submersion while maintaining optimal strength and durability.

Advantages of Underwater Concrete

Seamless Integration: Underwater concrete seamlessly integrates underwater structures with those above the waterline, resulting in cohesive and functional designs that harmonize with their surroundings.

Enhanced Structural Integrity: This type of concrete exhibits robust structural integrity, capable of withstanding water pressure, erosion, and other forces that are inherent to underwater environments.

Erosion Resistance: Underwater concrete is formulated to resist the erosive effects of water currents and abrasive particles. This quality extends the lifespan of underwater structures, reducing the need for frequent maintenance.

Leakage Prevention: The specialized composition of underwater concrete minimizes the risk of water seepage. This is a crucial advantage, as it prevents unwanted leaks and water ingress, preserving the integrity of the structure.

Tailored Adaptability: Underwater concrete can be tailored to accommodate specific underwater conditions. This flexibility allows for customization based on the unique requirements of each project, ensuring optimal performance.

Disadvantages of Underwater Concrete

Intricate Placement Processes: Placing concrete underwater involves intricate processes that require specialized equipment and skilled labor. This adds a layer of complexity to construction projects, which must be managed effectively.

Quality Control Challenges: Monitoring and maintaining the quality of underwater concrete can be challenging. Factors such as water turbulence and variable environmental conditions pose challenges to ensuring consistent quality.

Curing Complexity: Proper curing of underwater concrete is essential for achieving the desired properties. However, underwater conditions can complicate the curing process due to fluctuations in temperature and hydration.

Applications of Underwater Concrete

Marine Structures: Underwater concrete plays a pivotal role in the construction of marine structures such as piers, wharves, breakwaters, and seawalls. These structures require durability and stability against the forces of the sea.

Dam Foundations and Reservoirs: The construction of dam foundations and underwater portions of reservoirs heavily relies on the use of underwater concrete to ensure long-term structural integrity.

Tunnels and Bridges: Underwater tunnels and foundations for bridges are notable examples of structures that benefit from the utilization of underwater concrete to withstand underwater pressures.

Repair and Maintenance: Underwater concrete also finds its place in the repair and maintenance of existing underwater structures, ensuring they continue to function effectively.

Methods of Pouring Underwater Concrete

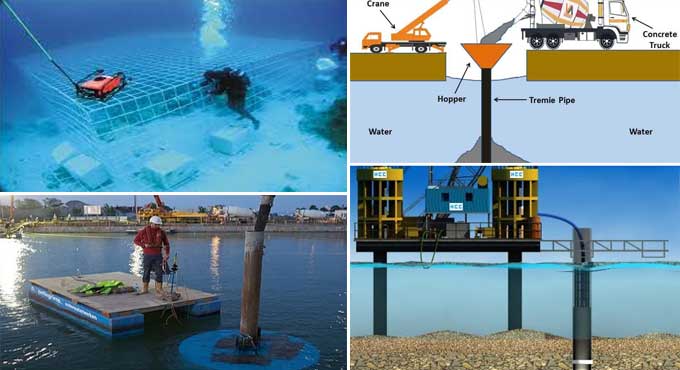

Tremie Method: The tremie method is a widely used approach for placing underwater concrete. It involves using a tremie pipe to deliver concrete to the desired depth. As the pipe is lowered into the water, the concrete flows through it, displacing the water and ensuring direct placement.

Pumped Concrete: Pumped concrete is another technique where concrete is transported through a pipeline to the underwater location. Proper pipeline design is essential to prevent segregation and ensure even placement.

Production of Underwater Concrete

Concrete Mix Design: The mix design for underwater concrete is tailored to meet the specific requirements of underwater applications. Factors such as water-cement ratio, admixtures, and aggregate gradation are carefully considered.

Special Admixtures: Underwater concrete often incorporates special admixtures that enhance workability, cohesion, and setting time. These admixtures optimize the properties of the concrete for underwater conditions.

Batching and Mixing: Precise batching and thorough mixing are paramount to achieving uniformity and optimal properties in underwater concrete. This stage ensures that all components are uniformly distributed.

Uses in the Field of Construction

Coastal Protection: Underwater concrete structures safeguard coastlines from erosion and wave impact, preserving the natural environment while providing stability to coastal areas.

Enhancing Maritime Activities: Structures such as piers, jetties, and harbours constructed using underwater concrete facilitate efficient maritime activities, promoting trade and commerce.

Hydropower Generation: Underwater concrete forms the foundation and structural elements for hydropower plants, ensuring efficient energy generation from water resources.

Infrastructure Expansion: The construction of underwater tunnels and bridges enhances urban infrastructure, improving connectivity and accessibility.

Limitations of Underwater Concrete

Placement Complexity: The placement of concrete underwater involves complex processes, including specialized equipment and skilled labour. This complexity adds to project challenges.

Quality Control Challenges: Ensuring consistent quality and proper curing pose challenges in underwater conditions, demanding rigorous monitoring and management.

Environmental Impact: The production of underwater concrete may have environmental implications, particularly if not managed responsibly. Mitigation measures are crucial.

To get more details, go through the following video tutorial.

Lecturer: Anime_Edu - Civil Engineering Videos

Considerations and Tips for Success

Comprehensive Planning: Thorough planning is essential, taking into account water currents, depths, and environmental impact to ensure a successful construction process.

Skilled Workforce: Engage skilled divers and construction professionals experienced in underwater concrete placement. Their expertise is critical to achieving optimal results.

Adaptability and Flexibility: Be prepared to adapt techniques and methods based on changing underwater conditions to ensure successful placement and compaction.

Quality Assurance: Implement stringent quality control measures to ensure that the desired properties of underwater concrete are achieved consistently.

Curing Strategies: Utilize effective curing methods that account for variations in underwater temperature and hydration rates. Proper curing is essential for concrete strength.